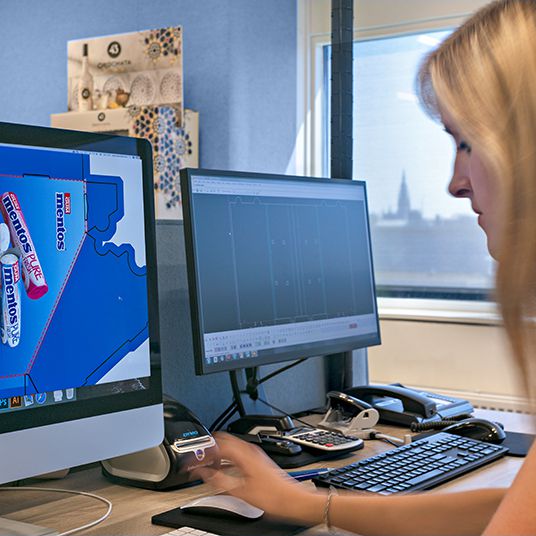

Digitalization and automation conserve valuable resources in production and can make paper-based packaging even more sustainable. Schumacher Packaging is the pioneer in modern high-performance digital printing, which is considered the most flexible and environmentally friendly printing process in the industry.

It combines high speed with high-quality, multi-colored print images - whether on brown outer liner, open flute or internal printing. In addition, the technology does not require any clichés or printing plates and only uses water-based and food-compliant inks. Shorter lead times ensure leaner processes and also allow changes to the print image at short notice.

Fast, colourful, sustainable –

ground-breaking advantages of digital printing

Digital printing for digital influencer:

Transport packaging with a wow effect

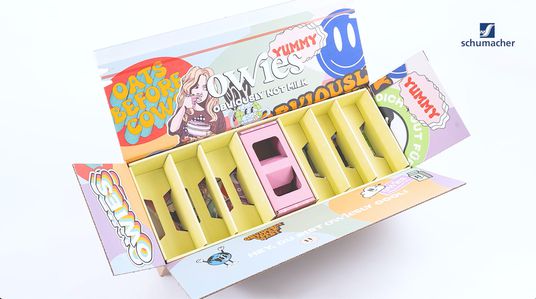

In the fall of 2023, Dagi Bee, one of Germany's best-known YouTubers, launched a plant-based milk alternative, which she sells online. The "Owies" oat milk can be ordered both in trays and in bundles, i.e. sets consisting of several products (e.g. tetra pack and jars). For the latter option, the influencer needed high-quality transport packaging in which her products could be safely delivered to the end customer.

At the same time, these logistics solutions also had to do justice to the Internet star visually by standing out and being memorable. Thanks to innovative digital printing technology, we created a magnificent print image that gives all "Owies fans" real wow moments when unpacking. The digitally printed transport packaging is made of kraftliner paper, so just like the oat milk, it is of purely natural origin and therefore completely environmentally friendly. "Cow "le thing.

Digital solutions for your industry too

Medium and large quantities of the same design can be easily split and printed with different images - whether seasonal, regional or personalized. Consecutive barcodes and QR codes can also be printed directly onto the packaging, eliminating the need for labeling. The flexibility and diverse opportunities for individualization open up completely new marketing potential for retailers that is not possible with classic flexo or offset printing.

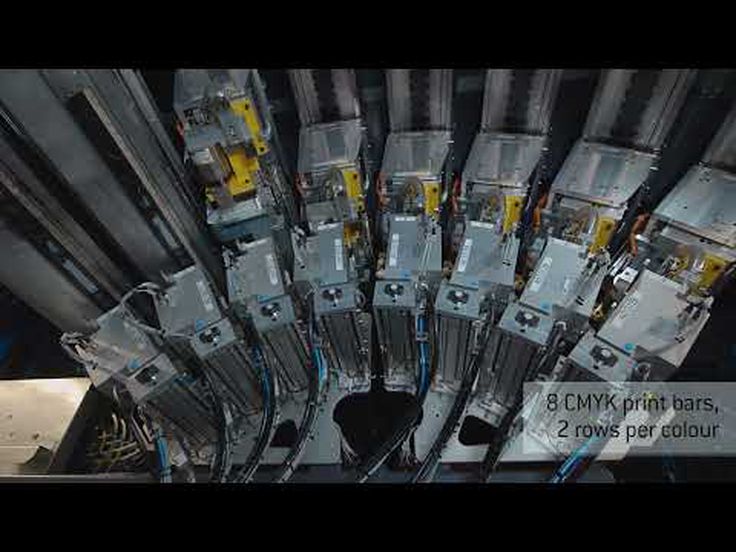

The BHS Jetliner - digital printing inline with the corrugator

In spring 2021, we put the BHS Jetliner, a newly developed, highly efficient digital printing machine, into operation at our Greven site. It is the result of many years of development cooperation between Schumacher Packaging and BHS Corrugated Maschinen- und Anlagenbau GmbH.

The RSR process (roll to printed sheet in real time) from BHS Corrugated differs fundamentally from all digital printing solutions on the market. This is because digital printing takes place parallel to the production of corrugated board. Since there is no need for post-printing, we produce your packaging even leaner, faster and therefore more sustainably.

High-speed digital printing for medium and large print runs

We have been using the innovative single-pass digital printing technology for medium and large print runs on an industrial scale for years now, and have gained significant experience with this technology .

In single-pass digital printing, the quality of the paper does not play a major role. Even on coated white or brown grades and on single-face board, you are guaranteed to achieve high-quality print results with a modern, sustainable look.

Durst/KBA SPC 130

Our postprint digital printing machines from Durst/KBA print sheets up to a length of 2,600 mm with brilliant, multicoloured print images.

Read

also

CONTACT US.

We make custom solutions possible

with digital printing.

Hello!

My name is Jochen Drösel. My team and I are the people that make things happen at Schumacher Packaging. However unique your requirements, we create custom solutions, perfectly tailored to your needs. We look forward to hearing from you!